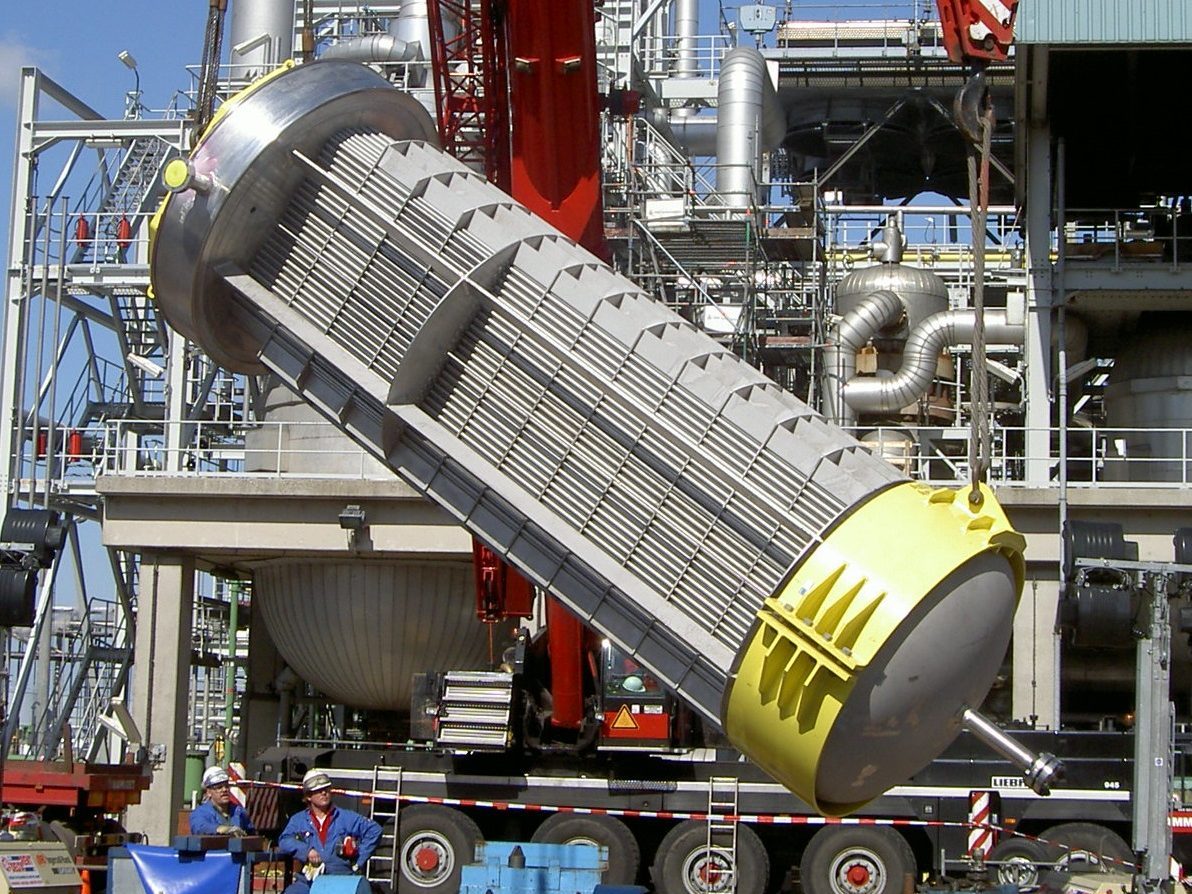

A heat exchanger is a device that is used to transfer heat from one medium to another without them coming in direct contact with each other. Heat exchangers are widely used for refrigeration, air conditioning, space heating and in power stations, (petro)chemical plants, petroleum refineries, natural-gas processing and sewage treatment.

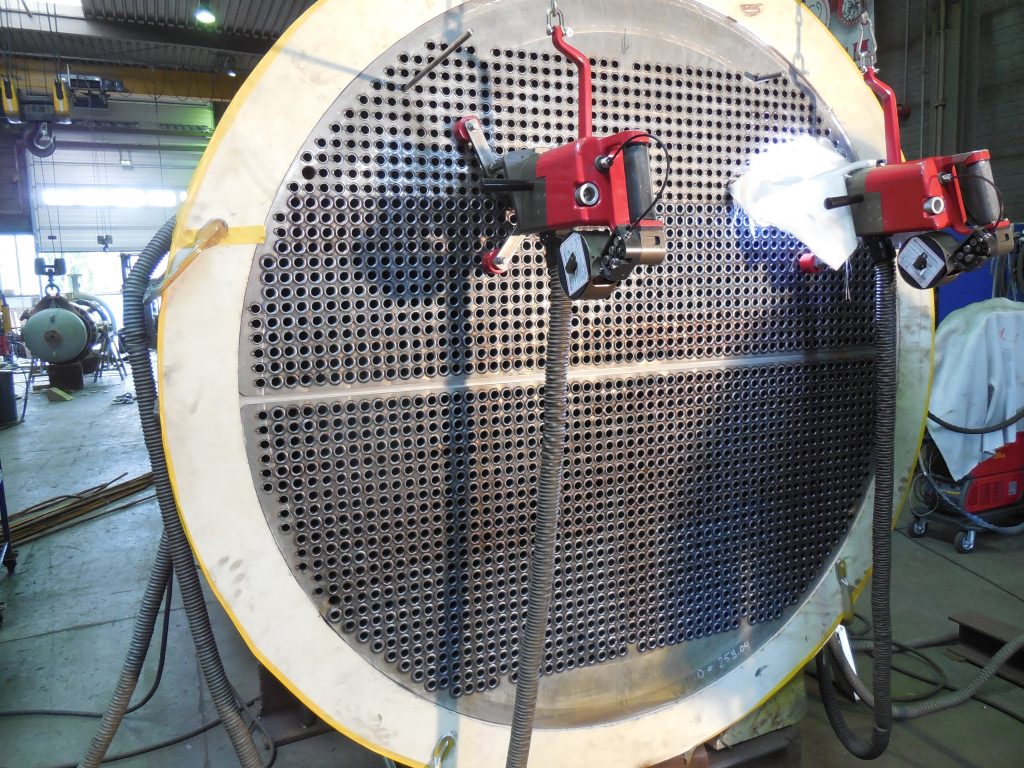

The most common are “Shell and Tube” heat exchangers. These Heat Exchangers exist out of three types; Fixed Tubesheet, Floating Head and U-Bundle. In a Fixed Tubesheet Exchanger the tubesheet is fixed to the shell. Thermal expansion is very limited but this can be compensated through an expansion bellow in the shell. In a Floating Head Exchanger the tubesheet at the rear end is not fixed but allowed to float, which allows for thermal expansion and the tube bundle to be removed for cleaning. An U-Bundle allows for “unlimited” thermal expansion and the tube bundle to be removed.

There are many options in the choice of materials or combination of materials. Obviously this is fully driven by your process characteristics. Oostendorp can handle a wide range of materials, from common Carbon Steel to Tantalum. Feel free to contact us for more details.